History

Founding year 1919

1921

At that time people were enthusiastic about radio. But radios were missing and parts for military devices (appliances) were in short supply. Richard JAHRE realized the necessity of producing coils, clamps, detectors and mica capacitors in series. The young company was able to produce and ship them.

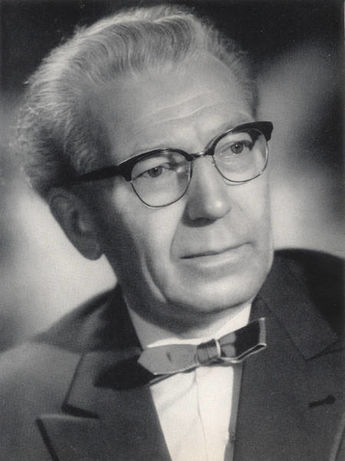

Photo: Company founder Richard JAHRE at the age of 64.

1924

1934

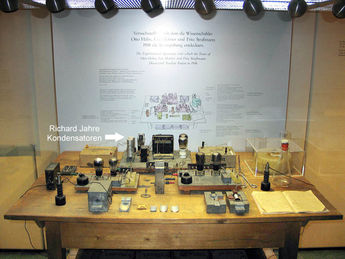

The program is growing: Capacitance-standard, standard-decades, triple decades, peg-standards for measurement. The tolerance is 1 ppm, the loss factor is less than 0.1 per mille.

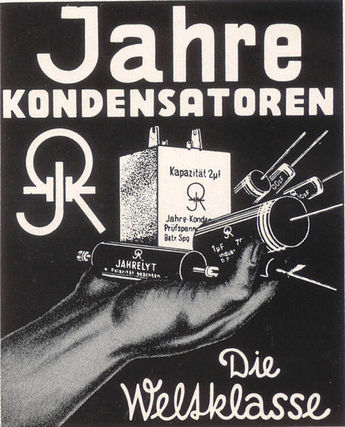

Precision capacitors transmitter types, HK fixed coupling capacitors.

Pico-block and micro-block, roll-type capacitors with mica and paper, paper capacitors in the cup, elcos in bacelite, cardboard tubes or aluminum cups for the radio technology.

The plant Richard Jahre, manufacturer of capacitors in Berlin, Köpenicker Str. 33a grows to 7,000 square meters and 400 employees. The daily production is 60,000 capacitors. The branch in Paris has 100 employees.

1938

1944

The plant in Köpenicker Straße was completely destroyed by bombs. Within 4 years the rebuilding was effected.

But the result of the "iron curtain" was the dispossession because the Köpenicker Straße is situated in the Eastern

part of Berlin.

1954

1959

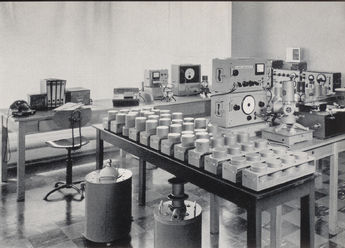

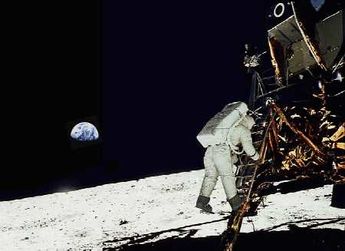

Point-to-point radio system, radar, radio astronomy and rockets need reliable, robust, precise and small components. Richard Jahre develops and produces the necessary ectronical components. With 225 employees at 3,000 square meters the production is carried out 10 years after the new beginning. 25 % are exported.

1965

The new factory in Berlin, Lützowstraße with 6,000 square meters is completed. r, Richard Jahre, the founder

of the company, sells the company to Roederstein.

1966

Roederstein sell the company Richard Jahre to Signal Apparatefabrik Julius Kräcker AG. Richard Jahre is a

self-contained company within this group. The company Richard Jahre is changed into a limited partnership (KG).

Further a company Richard Jahre GmbH is founded in Stuttgart.

1969

1975

1977

The company Richard Jahre GmbH is transferred to Wilhelmshaven.

1979

1986

1990

Richard Jahre KG are dissolved. Richard Jahre GmbH overtakes the branch capacitors and inductors.

The mica slices are produced in the new founded company Möricke.

1994

The company's founder - Richard Jahre - dies at the age of 99 years. He has got high honours, for instance

the Diesel Gold Medal and the Federal Service Cross 1st Of Merit of the Federal Republic of Germany.

1996

Richard Jahre GmbH overtakes the company Möricke. Now under the same roof again are together all products.

2002

2008

In December the family Eibenstein from Oldenburg buys Richard Jahre GmbH.

2010

2011

2012

The company Richard Jahre receives in February 2012 the entrepreneur's prize of the general Wilhelmshaven - Friesland for the quality standard of the products and the Innovative power of the company.

On 3 April Hans-Werner Kammer, a member of the houses of Parliament, visited the Richard Jahre Production facility in Wilhelmshaven and the TZÜ® sensor warning system for hall roofs explain. "I can well imagine that such sensors will be mandatory in large halls To prevent accidents, "says Hans-Werner Kammer. "This technique from Wilhelmshaven Can save lives! "

On 1 October 2012 the Richard Jahre GmbH takes over the 1923 founded in Oldenburg and today in

Wilhelmshaven-based company Mangels.

2018

2019

2021

Introduction of laser marking of electronic components.

2022

The path to CO2 neutrality by putting a PV system into operation on the roof of our production building. The company produces 33% more electricity with the system than will be consumed in the whole of 2022, and the excess electricity will be released into the public power grid.

2023

Start of digitalization and production with robots in our production.