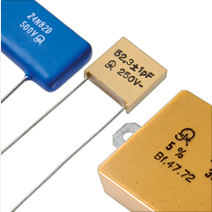

Mica capacitors

Small capacitors

- Small and compact

- Capacity: to 2,2 µF

- Voltage: to 3 kV

- Power: to 12 A

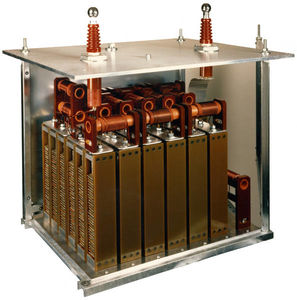

- Maximum Performance

- Capacity: to 6 µF

- Voltage: to 50 kV

- Power: to 250 KVA

- Precise square pulses

- From mica capacitors

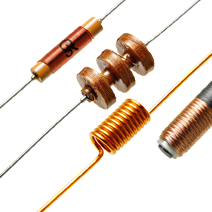

- From inductors

- In combination

- Accurate capacity

- AC voltage: to 30kV

- Nominal loss: = 1 x 10-5

- With measurement log

The decisive advantages of mica capacitors.

- A nearly frequency-independent loss factor.

- The very high operating reliability.

- Long-term stability.

- Can be used at elevated operating temperatures.

- Extremely low induction.

Our capacitors have properties which can only be achieved with the dielectric mica.

- The mica capacitor has been since the beginnings of a widely used telecommunication device, and yet as modern today as then. Especially when higher demands on operational reliability, stability and operational capability will be provided at elevated temperatures, provides the mica capacitor as an ideal device with low loss and small Temperature coefficient.

- The manufacturing and materials is larger than other capacitors, so the benefits offered by the mica, and the technical capabilities that are not yet fully exploited to some extent, overlooked.

- The quality of a mica capacitor is influenced by the mica used in places which is worsened particularly by air bubbles, foreign inclusions and pores. The use of thicker mica with lesser quality might reduce the risk of default, but not eliminate. The isolation distances must be measured because of the relatively high test voltage 2 to 3 x Un abundant, but also to achieve a good insulation resistance, so that in continuous operation at nominal voltage occur virtually no Randüberschläge.

- In continuous operation at rated voltage and an ambient temperature of 100 ° C can be expected for mica capacitors with 10 high 7 Component hours. At 1000 elements is on average after 10,000 hours, a failure to be expected, unless special factors make themselves felt, which may arise, for example, impregnation or by decomposition of the wrapping. Such effects are observed in type tests after 5000 hours or more when using unsuitable materials.

- By reducing the voltage by 30% the life experience is increased by a factor of ten. If a 500 V capacitor is operated at 30 V, extends the service life of more than 1000-fold.

- The mica capacitor is relatively insensitive to ambient temperatures of -55 ° C to +150 ° C, when the wrapping and eventual impregnation are sufficiently stable to heat. The mica itself and resist the occupation Einbrennversilberung withstand operating temperatures of +350 ° C.

- Long-term studies have shown that when kunstharzumhüllten small capacitors after 5 years of weathering) in Central European climate (light rain and shaded in urban air storage capacity of the temporal consistency is better than 1 x 10-3. Endurance tests on the 1.5 times rated voltage at the maximum ambient temperature of +85 ° C to +125 ° C than 100,000 hour show that quality capacitors to achieve a stability better than 0,3%.

- Temperature coefficient of the scatter generally 10 to 40 x 10-6 ° C and can be by design and packaging technology influenced in certain extent. The loss angle is normal in 5, compared x 10-4 at 1 MHz. At higher frequencies the losses are largely determined by the geometrical construction. So-called Verklatschungskondensatoren with band connections at 50 MHz to achieve a loss angle of 10 x 10-4.

- For small capacitors are mainly mica sheet thicknesses from 20 to 35 µ processed at voltages from 125 V to 1000 Mica V but it can also split in leaf thickness 1 to 2 µ, ie the corresponding reduction in operating voltage of 10 V to 30 V, which for many applications is sufficient, would reduce the existing condenser volume to 10% to 20% or a 10,000 pF capacitor could be manufactured with dimensions of 2.5 x 5 x 5 mm, and connecting wires in a 2.5 mm pitch, if they succeed in manufacturing technology, such to process thin film.

- What is new is the production of several partial capacities that belong to a network on a mica sheet. The multi-assignments will be made of silver aufgebrannt to single sheets. By stacking several such papers, which are then sintered at about +500 ° C, then there is the complete C-network that is interconnected with coils or resistors to filter or attenuators. For harmonic filters are grouped together for example, five capacities in a sintered block, which has only four external ports. Depending on the capacity is reached, a tolerance of 2% to 5%.

- Are advantageous in the described embodiment, the small dimensions and a smaller manufacturing cost in large quantities. However, several individual capacitors grouped in the same housing space savings arise and require less assembly labor in the finishing. This power is an increasing degree, especially in mica capacitors made use who are on their cuboidal building a good space utilization, in combination with the other benefits mentioned.

- The sintering of several printed with conductive silver paint to a block of mica sheets is not new. These so-called mica chips are soldered directly without connecting wires and wrapping with solderable metallized sinter pages in printed or etched circuits. In addition to the significantly reduced dimensions creates an almost induktivitätsloser structure, which is also suitable for frequencies up to GHz.

- The characteristic of mica capacitors stacking technique is particularly beneficial for performance and high-voltage capacitors. It allows short and flat layouts and electrode connectors, the strength of the required line resistance and the dissipated heat loss can be matched with the lowest possible inductance. Partial capacitances can be picked up in almost any number of particularly compact design. The capacity of tolerance can narrow down to 1%. To derive the heat loss more chilling to choose from. Usually at low pressure to achieve cooling by forced air or cooling water. As an example of a water volume attainable power capacitor resonant circuit is added, the cm was installed in an enclosure of 30 x 30 x 25 for a reactive power 2MVA at 1 MHz. The capacitor has a capacity of 0.03 Voltage and an operating voltage of 3 kV. A Kühlölkreislauf via heat exchangers may under certain circumstances offer advantages over conventional methods.

- To generate high voltage pulses with high output rapprochement with rectangular or trapezoidal current and voltage over several mica film capacitors with LC coils are interconnected networks. These chains run thus far in the relatively small size, max. 6 ?sec. Long pulses of 20 kV and 2 KA with a pulse repetition frequency of 50 Hz was produced, are preferably used in radar technology. The evolution to even higher performance is possible.